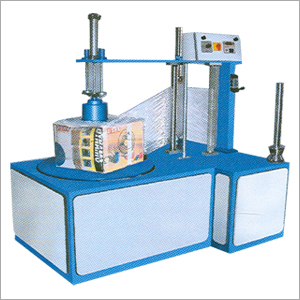

Box Wrapping Machine

Product Details:

- Product Type Wrapping Machine

- Material Stainless Steel

- Voltage 220 to 420 Volt (v)

- Power 230/50 Volt (v)

- Rotating Speed 3-12 RPM

- Dimension (L*W*H) 1,200 x 1,200 x 2,200 Millimeter (mm)

- Weight (kg) 100-150 Kilograms (kg)

- Click to view more

Box Wrapping Machine Price And Quantity

- 1 Unit

- 150000 INR/Unit

Box Wrapping Machine Product Specifications

- 100-150 Kilograms (kg)

- Yes

- Wrapping Machine

- 3-12 RPM

- 230/50 Volt (v)

- Stainless Steel

- 220 to 420 Volt (v)

- 1,200 x 1,200 x 2,200 Millimeter (mm)

Box Wrapping Machine Trade Information

- 25-30 Unit Per Month

- 2-3 Week

- All India

Product Description

With the intention of providing utmost satisfaction to the clients, we are offering to them a high quality series of Box Wrapping Machine. Electrically operated, all these machines are cautiously assembled by integrating quality components and raw materials. Across different packaging industries, all these machines are used for excellent wrapping of electronic, food, garments, engineering, pharmaceutical and chemical boxes. We make available the stock of Box Wrapping Machine at feasible pricing structures.

Features of Box Wrapping Machine:

- User friendly in design, require low maintenance and manual training

- Made to cater numerous requirements of packaging in industries

- Available with the adjustable wrapping plates

- Very efficient machine, less electricity consumption and all around close design ensures

- High speed blower system with continuous rating

- High quality heating element With cooling system

- Machine can be easily attached with other packing machine

- It can automatically group the product into package

Specification

Commodity | L-type sealer with Conveyor |

Voltage | 220V 50-60HZ |

Heater power | 2KW adjustable |

Conveyor speed | 0-15m/min |

Max sealing size(LxW) | 550 x 450mm |

Max conveyor loading | 25kg |

Packing size(LxWxH) | 1470*820*970mm |

Machine weight | 95kg |

Cutting film | POF,PVC,PP,PE |

Machine Dimension | 6" Height x 20" Length x 15"Width |

Control | Digital temperature controllers. |

Packaging & Delivery

- Packaging Detail: High quality Box Wrapping Machine

- Delivery Detail: With on 15 to 20 weeks after confirmed purchase order

Robust Construction

Crafted from premium stainless steel, this box wrapping machine ensures superior strength and longevity, making it suitable for demanding environments. The robust frame supports heavy and large boxes, delivering reliable operations for various packaging requirements.

Flexible Power Compatibility

Operating between 220 to 420 Volts and equipped with a power specification of 230/50 Volt, this machine adapts to different industrial electrical setups. This flexibility allows seamless integration into diverse work environments across India.

Enhanced Packaging Efficiency

With a rotating speed adjustable from 3 to 12 RPM, the machine streamlines the wrapping process, boosting productivity while maintaining consistent packaging quality. Its efficient operation minimizes material waste and reduces labor costs.

FAQs of Box Wrapping Machine:

Q: How does the Box Wrapping Machine improve packaging operations?

A: The machine automates the wrapping of boxes, ensuring uniform application of wrapping material. This increases operation speed, reduces manual labor, and enhances package security for transit or storage.Q: What types of boxes can be wrapped with this machine?

A: Thanks to its dimensions and durable build, the Box Wrapping Machine accommodates multiple box sizes, including bulkier and heavier packages weighing between 100-150 kilograms.Q: When should I choose this machine for my packaging needs?

A: This machine is ideal when high-volume, efficient, and reliable packaging is required, especially in industrial, warehousing, or distribution sectors. Its robust design suits continuous use and high workload demands.Q: Where is the Box Wrapping Machine available for purchase in India?

A: It can be sourced from authorized importers, manufacturers, suppliers, and traders throughout India, ensuring comprehensive support and service across the country.Q: What is the process for operating the Box Wrapping Machine?

A: To operate, place the box on the platform, select the appropriate rotating speed (3-12 RPM), and engage the wrapping mechanism. The machine will automatically rotate and apply wrapping material around the box uniformly.Q: How does the warranty benefit users of the Box Wrapping Machine?

A: The included warranty covers manufacturing defects and certain operational issues, providing peace of mind and reliable after-sales support for all users.Q: What are the primary benefits of using this stainless steel wrapping machine?

A: Main advantages include durability, flexible voltage compatibility, efficient packaging throughput, and reduced manual workload, resulting in lower operational costs and improved package safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+